Material Handling

Automate material flow with mobile robots and autonomous forklifts that adapt to your operations.

Material Handling

Automate material flow with mobile robots and autonomous forklifts that adapt to your operations.

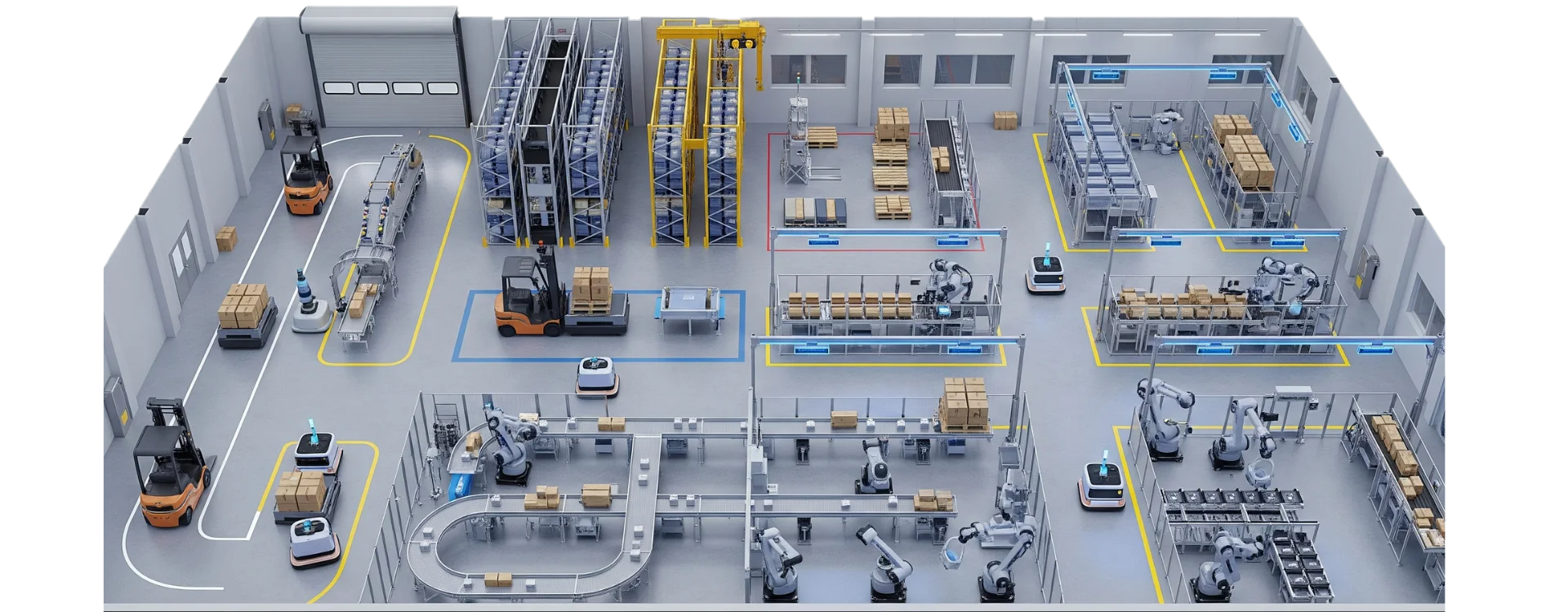

What is Material Handling Automation?

Material handling automation is the use of robotics and smart systems to move goods and materials efficiently within a facility. Instead of relying on manual transport, automated solutions like Autonomous Mobile Robots (AMRs)and autonomous forklifts handle tasks such as pallet movement, line feeding, replenishment, and order picking support.

40%

Productivity Gain

>10%

Infra Change

70%

Injury Reduction

100%

Fleet Scalability

Key Advantages

Material Handling Robots

Autonomous Mobile Robots (AMR)

AMRs are robots designed to transport any payload through dynamic environments. They navigate autonomously, avoid obstacles, and connect with WMS, ERP, or MES systems.

Example Applications:

- Order Picking Support – Move picked items to packing or consolidation.

- Line Feeding – Deliver parts directly to production lines.

- Replenishment – Move goods from storage to forward picking zones.

- Inter-Process Transport – Transfer items between workstations, storage, or QC.

Autonomous Forklifts

Autonomous forklifts combine traditional lifting power with robotic navigation.

They move pallets safely, integrate with racks, and optimize pallet flows across facilities.

Example Applications:

- Inbound & Outbound Pallet Transport – Move pallets between docks, storage, and shipping.

- High-Bay Storage Access – Store and retrieve pallets in racks automatically.

- Trailer Loading & Unloading – Automate dock operations for safer, faster handling.

- Cross-Facility Pallet Flow – Move pallets between production halls or staging areas.

Your Flow, Automated

We design material handling systems around your operations combining AMRs and forklifts with conveyors, AS/RS, and ERP/MES/WMS integration for seamless, end-to-end goods movement.